A modern solution for better construction from a Bengaluru based company

The Autoclave Aerated Concrete Block, or more popularly, AAC Block is a happening, smart and green building material now widely used all over India. Made by a Bengaluru based company that's always on the look out for contemporary innovations in building materials, Meghalite AAC Block has emerged as the most preferred substitute and is fast replacing conventional Red Clay Bricks, CC Blocks, Fly Ash Bricks, CLC Bricks and so on, which were used in building walls in residential, commercial and institutional construction until now.

A modern solution for better construction, Meghalite AAC Blocks comprise 60 - 65% Fly Ash (by weight), with other elements being OPC Cement, Quicklime, Aluminum powder and Gypsum. With such strong composition, no wonder Meghalite AAC Blocks are highly robust and durable despite their light weight. Also, this AAC Block’s solidity owes its origins to the calcium silicate and from the process of curing in a pressurized steam chamber called an Autoclave.

Meghalite AAC Blocks Features

A BRIEF HISTORY AND ADVANTAGES OF AAC BLOCKS

While AAC has been produced for more than 70 years, and though it offers several significant advantages over other cement construction materials since decades, it is only now being recognised in the construction industry for its lower environmental impact. Furthermore, AAC has many more advantages. Such as:

MEGHALITE AAC BLOCKS BENEFITS

FIRE RESISTANCE

| Wall Thickness | Resistant up to |

|---|---|

| 6 in | 6 hrs |

| 4 in | 4 hrs |

| 2.5 in | 2 hrs |

| 2 in | 1 hrs |

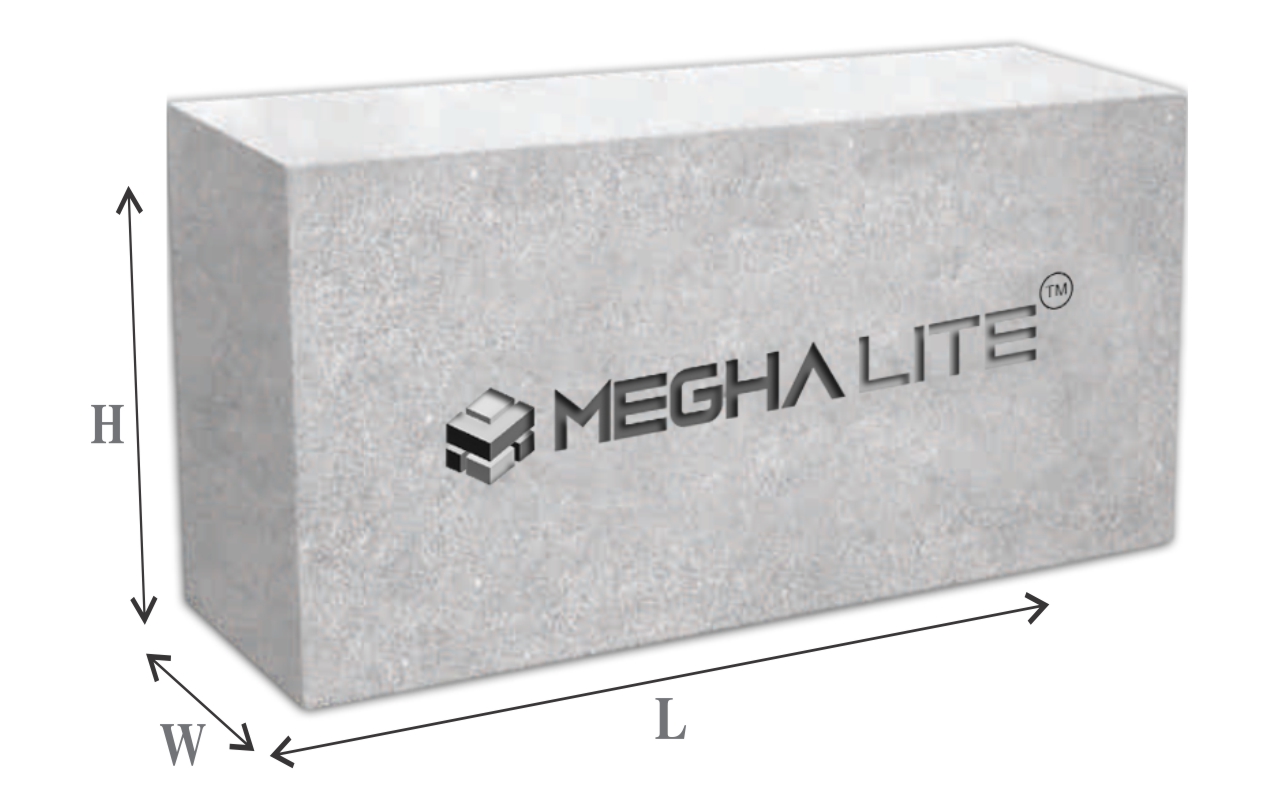

EASILY CUSTOMIZED INTO DIFFERENT SHAPE AND SIZE

| Length(L) | 600mm | 24" |

| Height(H) | 200mm | 8" |

| Width(W) | 100/150/200/225/250/300 mm | 4"/6"/8"/9"/12" |

TECHNICAL SPECIFICATIONS

| Perticulars | Units | Values | Requirement as per IS-2185 part-3 |

|---|---|---|---|

| Compressive Strength | N/mm2 | >4.0 | > 4.0 (Density range 551-650 Grade-1) |

| Oven Dry Density | kg/m3 | 560-640 | 551-650 |

| Fire Rating | Hrs. | 8.00(For 200ml wall) | 6 hrs in Desirable |

| Thermal Conductivity(k value) | W/mL | 0.16-0.21 | 0.24 Max |

| Sound Reductions | 45db for 200mm blocks without plastering | NA | |

| Modulous of Elasticity | Mpa | 2040 | NA |

| Thermal Resistance(R Value) | M2k/W | 0.95(200mm width)@021 W/mk | Max Value is Desirable |

| Thermal Conductance(U Value) | W/M2k | 1.05(200mm width)@021 W/mk | Min Value is Desirable |

| Drying Shrinkage | % | 0.04 | 0.05 for Gr-1Max |

| Sound Transmission Class | db | 44 | NA |

Technical Comparisons between Megha lite Aac Blocks (Vs) Clay Bricks

| Parameter | Meghalite AAC Blocks | Clay Brick |

|---|---|---|

| SIZE (LxHxB) | 600mm x 200mm x 75mm, 100mm, 150mm, 200mm & 230mm | 225mm x 100mm x 75mm |

| Structural Cost | Steel saving upto 15% | No Such Saving |

| Mortar Consumption/ Cu.M with 1:6 | 0.5 Bag of cement ( due to Flat, even surfaces & less no. of joints ) | 1.35 bag of cement ( due to irregular surface and more no. of joints ) |

| Breakage | Less than 3% | upto 15% |

| Construction Speed | Speedy Construction due to its big size, lite weight & easy to cut in any size or shape | comparatively slow |

| Quality | Uniforms & Consistent | Normally varies |

| Carpet Area | More due to less thickness of walls | Comparatively low |

| Availability | Any time | Shortage in Monsoon |

| Energy Saving | Approx. 30% reduction in air - conditioned load | No Such Saving |

| Chemical Composition | Sand/Flyash used around 60 - 70% which reacts with lime & cement to form AAC | Soil used which contains many inorganic impurities like sulphates etc. resulting in efflorescence |

| Precision in Size | Varition 1.00 ( +/-) mm | Variation 3.15 (+/-) |

| Compressive Strength | 3.5 - 4.5N/mm2 ( As per IS:2185 part III) | 2.5 - 3.0 N/mm2 |

| Sound Reduction Index1 (dB) | 45 for 20 mm thick wall | 50 for 230 mm thick wall |

| Thermal Conductivity (Kw-m/C) | It transfers heat between 0.21 to 0.42 W/mk | It transfer heat between 6-10 W/mk |

| Cost benefit factor | Savings up to 24% in structural cost due to reduction of dead load ( Subject to project design) | No Such Saving |

| Weight | 550 to 600 kg / Cubic Meter | 1950 to 2000 kg / Cubic Meter |

| Fire Resistance | 4 - 6 hrs depending on thickness | 2 Hours |

| Water Absorption | Should not be more than 10% of its weight ( If the block or Brick absorbs more water than the above specified limit, it causes adverse effect on the strength and durability | Should not be more than 20% of its weight |

| Moisture Resistance | Better than Red Brick | Average |

| Saving Plaster | Overall 35% cut down in the cost of plastering | No Such Saving |

| Environment Impact | Made up of ashes, thus does no soil is consumed | Around 32kgs of fertile soil is used to produce one brick |

| Maintenance | Superior properties of AAC blocks reduces the maintenance cost | Very High |

| Water Using during Manufacturing | Low, only used for auto - claving | High, need curing before use |

PROJECT IMPACT

Impact on project cost & Material usage when Meghalite AAC Blocks used as compared to Red Clay Bricks or Fly Ash bricks

| Material | Saving Of Material In % |

|---|---|

| Steel & Concrete | 10% |

| Plastering Material | 35% |

| Jointing Mortar | 60% |

| Wastage | 10% |